Ingrained reliability to the micrometer.

Horizontal thrust and support bearings for withstanding strong radial and axial forces.

Maximizing your plant’s availability was our benchmark when developing our innovative support bearings. Depending on the type, the bearing housings are available as pedestal, center flange (type SM) or saddle bearings. Operate them either with self-lubrication or with external lubricant supply. Some examples of our product lines:

- Our SN, D- and L-Series bearings are the choice for conventional marine drives with shaft line and hydro turbines and generators

- The SC line is designed as pedestal bearings and can support moderate axial forces in addition to high radial forces.

- Our SM series are specially designed for use as engine bearings in marine applications or as generator bearings in hydro applications.

Overview of our horizontal bearings

| Type | Size in mm | Shaft diameter in mm | Application |

| SC | 36-140 | 200-1400 | Electrical machinery, diesel generators, rolling mill drives, hydro turbines and generators |

| SM | 225 | 560 | Marine propulsion motors, hydropower, alternators |

| WG | 600-9000 | 200-1400 | Large electric machines, rolling mill drives |

| HG | 28-45 | 250-560 | Hydro turbines and generators, large electric machines |

| SN | 16-100 | 140-1000 | Shipbuilding (main propulsion), hydro turbines and generators |

| DN/DG/DR | 16-80 | 180-850 | Shipbuilding (main propulsion), hydro turbines and generators |

| LAR | 125-850 | Shipbuilding (main propulsion), hydro turbines and generators | |

| LR | 13-85 | 110-850 | Shipbuilding (main propulsion), hydro turbines and generators |

| I | 10-22 | 100-200 | Cement industry, tube mill drives, Crushers |

| IS | 10-52 | 100-520 | Heavy series for cement industry, tube mill drives, Crushers |

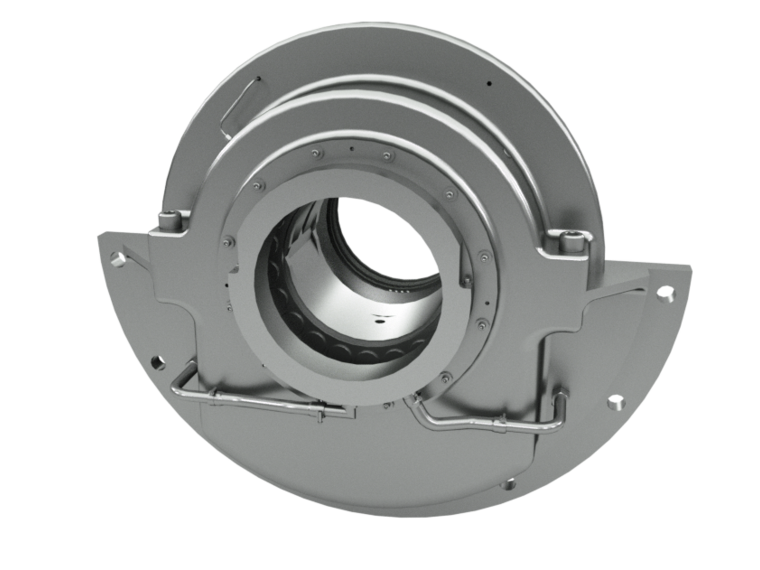

D type

RENK thrust bearings in the D range are suitable for absorbing high axial and radial forces, include shock type forces, regardless of the rotation and load direction. The key feature of the bearings in the D range are the RENK RS / RD slide shoes with a round running surface, which have a proven track record in many bearings in other ranges as well.

The bearings of the D type can be operated with natural cooling, water cooling, or external lubrication. The housings are designed as pedestal bearings, as saddle bearings with a lubricant sump, or as saddle bearings without a lubricant sump.

A bearing housing made of gray cast iron is used in the standard version. When it comes to special applications, we offer decades of experience in developing customer-specific solutions with bearing housings in welded designs.

HG type

RENK pedestal bearings in the HG range are self-lubricating slide bearings for high radial and axial load in conjunction with high speeds in a single direction of rotation, independent of the load direction. They were developed primarily for the mounting of hydro generators and electrical machines in stationary applications on land.

The key features of the HG bearings are the tiltable, round RENK RD slide shoes. These are supported via cup springs, thereby ensuring a uniform distribution of axial loads.

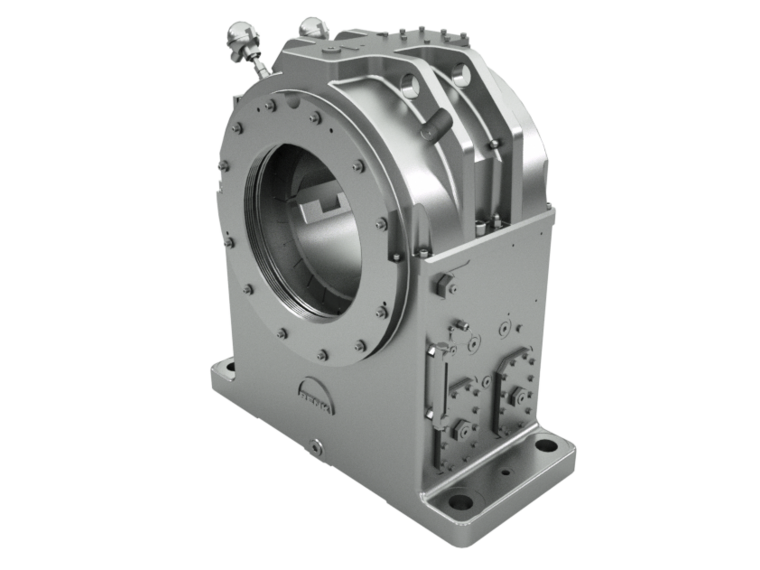

LA type

RENK thrust bearings in the AXILUS® LA range are designed to absorb high axial forces and are used in shipbuilding to absorb the thrust of the propeller as well as in general mechanical engineering applications or in the field of electrical engineering to absorb large axial forces in horizontal machine shafts. The bearings also absorb radial loads that occur.

In addition to the standard bearings in the various AXILUS® LA series, we offer custom solutions for special customer-specific requirements under the AXILUS® LAZ designation. Thrust measuring device, special strength requirements, overload protection, displacement compensation, noise reduction in the shaft train, and a nonmagnetic version are just a few examples of what we can do. As a systems supplier, we offer options such as shaft brakes, turn drives, or lubrication systems in combination with our thrust bearings. We identify package solutions that are specially adapted to the customer’s requirements.

LR/SN type

RENK marine shaft bearings in the RADILUS® range of type LR and SN are the proven standard for conventional marine propulsion systems with shaft lines. Both types are self-lubricating and can be configured as supporting bearings or journal bearings ‒ available with a lower shell only ‒ depending on the requirements. Because it is installed in the housing with a ball joint, the bearing shell adapts to the position of the shaft during assembly. Damaging pressure at the edges is avoided, and the assembly and alignment of the shaft train are simplified significantly.

The frictional heat is dissipated by means of natural cooling; i.e., through radiation and convection via the housing. If necessary, seawater resistant cooling systems can be built into the lubricant sump or the bearing can be connected to an external lubrication system.

The SN type is distinguished by a higher degree of radial rigidity of the bearing housing in contrast to the LR type. The SN type therefore has a proven track record with large sizes for special applications in particular – such as ice-going ships, for example.

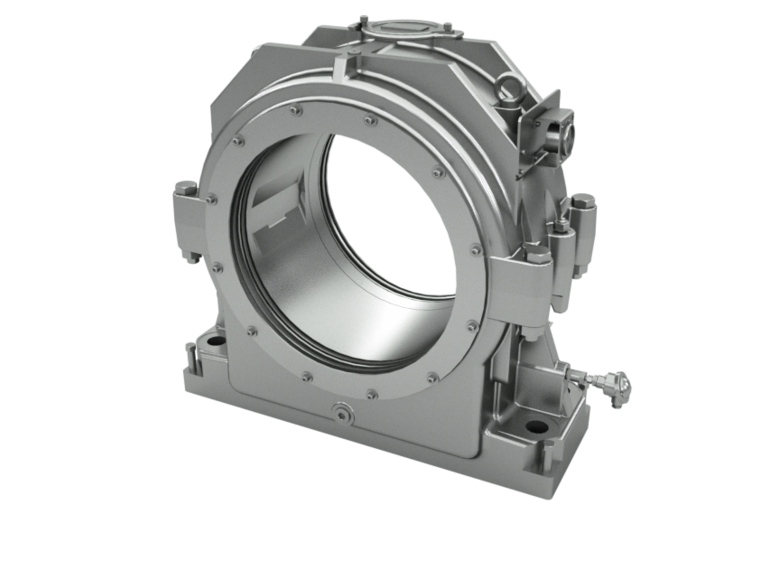

SC type

RENK pedestal bearings in the SC range are optimized for stationary use as radial bearings in land applications and can also absorb moderate axial loads. They are primarily used in electrical machines.

The versions can be assembled from a modular system depending on the needs of the respective situation. The SC range of bearings was constructed in such as way that it can also be used together with the familiar E bearing range. The shaft heights and the drilling pattern of the foot mount, for example, match those of the E bearings to a large extent.

Frictional heat is dissipated by radiation and convection alone in many cases. Two lubricant coolers made of seawater resistant material can also be used in the housing, and integrated baffles boost the cooling performance.

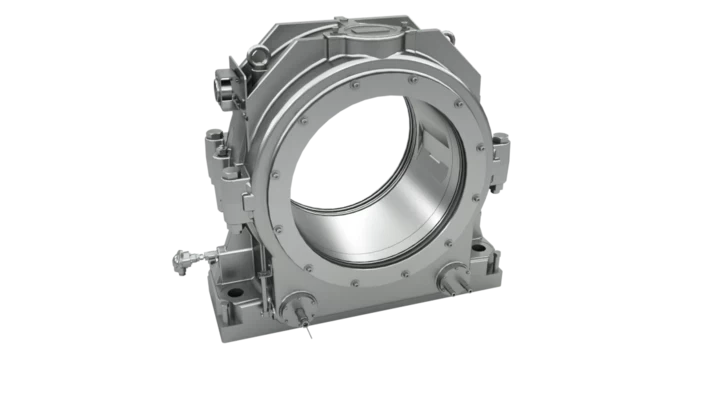

WG type

RENK rolling mill bearings in the WG range are designed for extreme axial strain. They were developed primarily for the mounting of rolling mill drive units and large electrical machines in which high axial loads occur at low speeds and a high level of protection against damage must be ensured at extreme loads.

This range incorporates the experience we have gained in numerous ranges of RENK bearings. Bearing shells from the SC range come into play here, for example, as well as seals from the E range of bearings and RENK RD slide shoes from the axial bearing area. Using these components therefore offers the advantage of simplified spare parts stocking. In many cases, fixed and floating bearings with the same radial parts and seals can be fitted. Meanwhile, the wear parts are stocked components to a large extent and can be delivered on short notice.

WG bearings have a welded housing, and its strength makes it suitable for withstanding maximum axial shock loads. WG bearings are therefore especially suitable for use as thrust bearings where expensive system components need to be protected against axial forces in the event of an accident. This compact construction and the optimized arrangement of the bearing elements have resulted in a cost-effective welded solution.

Should you have any questions or requirements concerning our

products, please don't hesitate to

reach out to us.

Get in touch with our experts in case of any questions: