RENK gear couplings - Sturdy and powerful.

Gear couplings from RENK impress with a high power density, long service life and a variety of possible combinations. They are particularly suitable for compensating axial, radial and angular misalignments as torsionally rigid shaft connections for form-fit torque transmissions. Their absolute reliability is also guaranteed in harsh environments or potentially explosive areas such as in mining.

RENK gear couplings

RENK Basic series

Our extensive product portfolio, including a wide range of series and variants, offers you complete freedom to design a shaft connection that fits your needs. It also gives you the certainty of selecting the ideal solution, even for the most difficult drive applications.

The gear couplings in the SB, SBk, and LBk series stand out for a high power density and a long service life. We employ a reliable oil or grease lubrication system for each series. They are suitable as torsionally rigid shaft connections for a positive torque transmission and provide compensation for axial, radial, and angular shaft misalignments. Gear couplings are truly all-purpose and are used in numerous different applications.

RENK High-speed series

Built on the basis of more than 75 years of experience in the development and production of these high-quality drive elements, RENK’s gear couplings in the high-speed series are the ideal product, especially when it comes to transmitting maximum speeds. Our high-speed series includes three different series. The ZT, TF, and TSB ranges are available in different variants to meet the needs of the respective application.

All of the ranges are tooth tip centered and equipped with a single tooth lubrication system. The existing high standard of quality ensures that components can be replaced. The high-speed series offer you a high level of protection against overloads with low axial forces. Our couplings are also optionally available in a API 671 version.

RENK Gear spindle couplings

The unique RENK gear spindle is completely interlocking and contributes to an extremely high performance capability.

RENK gear spindles are an enhance ment of the globally well recognized gear couplings. This shaft connection, which is torsionally rigid yet flexible in all directions, does not contain any flexible transmission elements and is therefore the ideal form lock fixing. The purely mechanical flexibility of the RENK gear spindle can be attributed to the special shape of the curved tooth. Axial, angular and radial shaft misalign ments are compensated by a flexibility in all directions. The tooth flanks remain capable of bearing the full load, resulting in the exceptionally high level of performance. Operators also benefit from the high level of availability and simple exchange of the elements.

Gear joint couplings

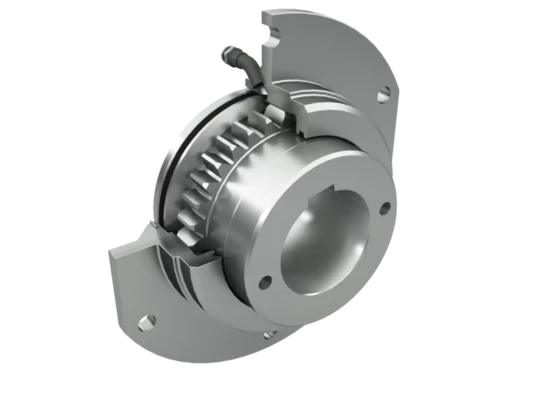

Gear joint couplings assume a double function as a connecting element between the drive unit and lifting device, for example in a crane and hoist device. In addition to transmitting the torque, the coupling supports the forces acting radially on the drum. The gear joint coupling is torsionally rigid, yet flexible in all directions, which offers significant advantages in comparison with a rigid coupling.

The gear joint couplings consists of the coupling hub with milled, curved toothing, which meshes with the coupling housing with beveled internal spur toothing. The coupling hub is fixed to the gear shaft. A cylindrical shaft seat with a keyway connection is typical. Other connections, such as a shrink seat or splined shaft, are also optionally available. The transmitted torque as well as the maximum permissible shear load can also be increased with additionally hardened toothing.

Gear joint couplings are primarily used in the area of hoisting and conveyor technology in crane hoists and hoisting drum drive systems.

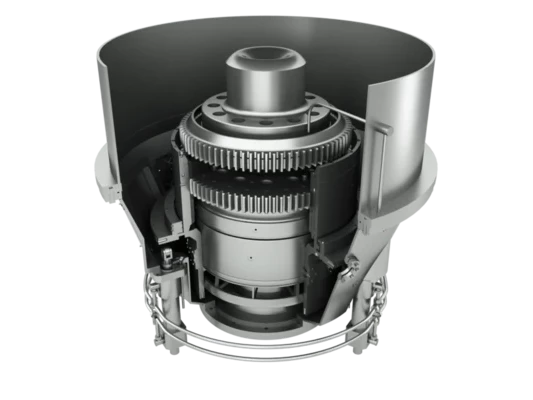

Shifting gear coupling

Shifting gear coupling. Engagement or disengagement. In any position

Complete flexibility: The gear coupling from RENK has always been available in a connectable design. The geared components can be engaged o disengaged at a standstill as well as during the synchronous operation of connected units. If neces sary, operators can thus temporarily disconnect certain machines of a drive train and connect auxiliary or alternative drives, if required.Tailor-made couplings from RENK are available in both horizontal and vertical designs. Shifting gear couplings are usually structured in a double cardanic design. This structure allows for the compensation of radial, axial and angular misalignments of machine shafts.

Consistency leads to success: The running and switching behavior of couplings always remains the same.

Get in touch with our experts in case of any questions: